Concrete Batching Plant Spare Parts

At Deshan Engineers, we offer a high-quality range of Concrete Batching Plant Spare Parts that ensure smooth and uninterrupted operation of your batching plants. Our spares include mixing blades, arms, liners, gearboxes, filters, sensors, conveyors, and more—suitable for all major plant models. Engineered for durability and precision, our parts help reduce downtime and boost productivity. Trusted across India, Deshan Engineers is your reliable source for efficient and long-lasting batching plant spares.

At Deshan Engineers, we specialize in manufacturing and supplying high-quality Concrete Batching Plant Spare Parts, designed to enhance the efficiency, durability, and reliability of concrete production equipment. With an extensive range of spare parts engineered to meet the highest industry standards, we cater to a wide spectrum of batching plants, including renowned brands like CONMAT, KYB CONMAT, MACONS, MAXMECH, SICOMA, VENUS, SCHWING STETTER, TERRA, AMRUTA, NILKANTH, and many more. Our batching plant spares are crafted using premium high chrome and mild steel materials, ensuring superior strength, wear resistance, and longevity. The durability of our spare parts helps minimize downtime and reduce overall maintenance costs, making them a valuable investment for concrete plant operators. We offer a comprehensive selection of spare parts, including mixer arms, mixing blades, paddles, liners, tiles, shafts, bearings, gearboxes, load cells, pneumatic cylinders, butterfly valves, discharge gates, vibrators, and other essential mechanical and electrical components that ensure smooth and uninterrupted operation. Specifically, our spare parts are designed to be compatible with SICOMA MAO 500 / 750 / 1500 / 2000 / 2500 / 3000 / 3500 / 4000, MSO 500/750 Twin Shaft Concrete Mixers, ensuring that our customers receive components that match OEM specifications and provide optimal performance. Our parts cater to batching plants with different capacities, including 0.5, 0.75, 1, and 1.5 cubic meters per hour, allowing us to serve a broad range of projects, from small-scale construction jobs to large infrastructure developments. At Deshan Engineers, we understand the critical role that concrete batching plant spare parts play in maintaining operational efficiency, which is why we only deal in brand-new spare parts that adhere to the highest quality standards. As a reputed manufacturer and exporter from India, we ensure that our batching plant spares are built to withstand the toughest working conditions in construction environments, from high-load operations to extreme weather exposure. Our commitment to quality and precision engineering ensures that every component we supply is reliable, durable, and delivers consistent performance. We maintain a large inventory of ready-to-ship spare parts, reducing wait times and ensuring that our clients receive prompt deliveries, no matter where they are located. The reliability of our products, combined with our customer-centric approach, has made us the preferred supplier for construction companies, ready-mix concrete plants, infrastructure developers, and government projects across India and internationally. As an industry leader, Deshan Engineers continuously invests in research and development to enhance our product offerings and keep up with the evolving demands of the concrete industry. Our batching plant spare parts are designed to optimize the overall efficiency of concrete production, reduce machine wear, and extend the service life of critical components. Our export-quality spare parts, manufactured with advanced techniques and precision machinery, ensure that plant owners and operators can maintain uninterrupted production with minimal maintenance requirements. Whether you are looking for replacement wear parts, maintenance components, or customized solutions for your batching plant, we provide a one-stop solution for all your concrete plant spare part needs. Our focus on customer satisfaction extends beyond providing superior products; we also offer expert technical support to help clients identify the exact spare parts they need, ensuring a hassle-free procurement process. By choosing Deshan Engineers, you are investing in high-quality spare parts, competitive pricing, timely deliveries, and unmatched customer support—all essential factors that contribute to maximizing the productivity and profitability of your concrete batching plant operations. With our Made in India commitment and a global vision, we continue to expand our reach, serving construction industries across different regions with unwavering dedication and excellence. When it comes to concrete batching plant spare parts, trust Deshan Engineers to deliver only the best in quality, reliability, and service.

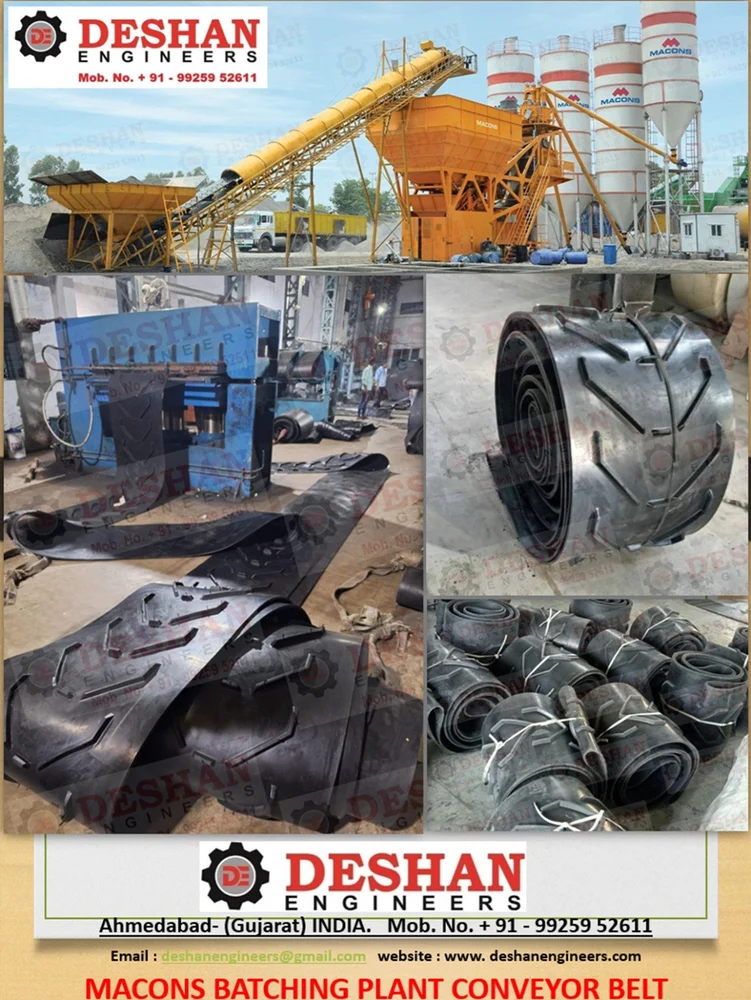

Concrete Batching Plant Conveyor Belt – Conveyor Belt For Concrete Batching Plant

Approx. Price: Rs 34,800 / PieceGet Latest Price

Product Details:

| Minimum Order Quantity | 1 Piece |

| Belt Thickness | 10 mm |

| Material | Rubber |

| Belt Width | More than 1000 mm |

| Model Name/Number | MA-12, MA-15, MA-18, MA-20, MA-25, MAC-20, MAC-25, MAC-30, MAC-45, MAC- |

| Usage/Application | Concrete Batching Plant Conveyor Belt, RMC Plant Conveyor Belt, Batching Plant Conveyhor Belt |

| Features | Heat Resistant |

| Application Area | concrete batching plant |

| Structure | Belt Conveyor |

| Brand/Make | MACONS, MAXMECH, APOLLO, VENUS, KYB CONMAT, NILKANTH, AMRUTA, AQUARIUS |

| Color | Black |

| Country of Origin | Made in India |

At Deshan Engineers, we manufacture high-performance conveyor belts designed specifically for concrete batching plants, ensuring seamless material handling with maximum efficiency and durability. Our conveyor belts are engineered to transport aggregates, sand, cement, and other raw materials with precision, optimizing the concrete production process while minimizing material wastage. Built with heavy-duty rubber belts, reinforced with high-tensile strength fabrics and advanced vulcanization technology, our conveyors offer superior wear resistance, high impact tolerance, and excellent flexibility, making them ideal for continuous, high-load operations. The robust steel frame structure ensures stability and durability, even in the most demanding environments, while the modular design allows for easy installation, expansion, and maintenance. Equipped with energy-efficient motors, precision rollers, and advanced belt tensioning systems, our conveyor belts guarantee smooth, noise-free, and reliable operation, reducing downtime and enhancing productivity. Additionally, we integrate advanced dust suppression and sealing systems to maintain a clean and eco-friendly work environment, preventing material spillage and dust emissions. Whether for stationary or mobile concrete batching plants, our conveyor belts are designed to handle high-capacity material flow, ensuring uninterrupted production and consistent concrete mixing. Backed by our commitment to quality, innovation, and customer satisfaction, Deshan Engineers’ Concrete Batching Plant Conveyor Belts are the perfect choice for construction companies, ready-mix concrete plants, and infrastructure projects looking for durable, high-efficiency, and cost-effective material handling solutions.