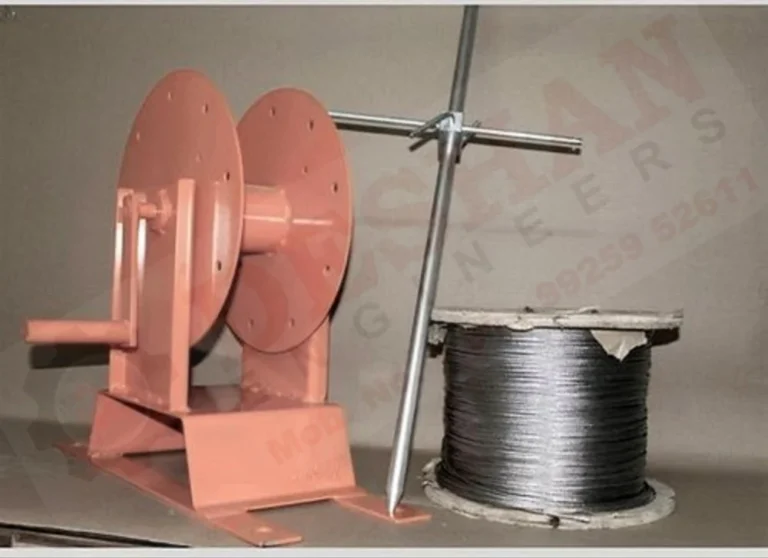

At Deshan Engineers, we understand that the reliability of your road construction machinery depends on the quality of the road construction machinery spare parts you use. That’s why we go the extra mile to deliver only the best. With a strong foundation in engineering excellence, we offer a wide range of road construction machinery spare parts known for their durability, precision, and performance. Whether you need components for Hot Mix Plants, Asphalt Plants, Batching Plants, Asphalt Paver Machines, Asphalt Drum Mix Plant, Kerb Paver Machines, Truck Mounted Bitumen Pressure Distributors, Bitumen Sprayer, Road Marking Machine, Concrete Plants, Concrete Road Cutting Machine, Asphalt Road Cutting Machine, Road Cleaner Machine, Hydraulic Road Broomer Machine, Concrete Pumps, Cement Silo Accessories, or Hydraulic Road Sweepers, we provide road construction equipment spare parts that are rigorously tested and built to last.

What sets us apart is our unwavering commitment to quality and customer satisfaction. Every product at Deshan Engineers is manufactured using premium-grade raw materials and modern production techniques to ensure optimal compatibility and long service life. Our team combines years of technical experience with a customer-first approach, ensuring that you receive not just parts, but smart, cost-effective solutions for your equipment.

With a growing presence across India, timely deliveries, and competitive pricing, Deshan Engineers has become the trusted choice for contractors, road builders, and machinery dealers. Choose us for our reliability, responsive support, and proven expertise in keeping your projects moving forward with zero compromise on quality.

Asphalt Mixing Plant Spare Parts – Essential components to keep your asphalt plant running efficiently.

Asphalt Mixing Plant Spare Parts – Essential components to keep your asphalt plant running efficiently.